High performance & sustainability, Emerging technology

The Net Zero Trailer can now be purchased through Craftsmen Industries, Inc. To request information, click here.

Why we built a Net Zero trailer and what we learned from the process

Last winter, we held Green Advantage training at a jobsite in Louisville. It was below 30 degrees that day. The meeting was held inside the jobsite trailer, and though indoors, everyone still felt the chill. Our team wore their coats and had a hard time concentrating. It's a pretty common situation across jobsites in the winter. In fact, one of the most frequent comments we receive in satisfaction surveys from the field is related to thermal discomfort.

Jobsite trailers are typically constructed of inexpensive materials, with no insulation and hard, rigid surfaces. As a sustainable contractor, we educate our clients on the value of resiliency, efficiency and lifecycle costs. We promote the impact of high performing structures on productivity, and yet, when it comes to our own work environments, we use inexpensive, inefficient materials. After all, they're temporary, right? Except, our jobsite trailers have been around for 20-30 years. They are only "temporary" to the particular jobsite they are serving. Once the project is over, the office is moved to the next jobsite. For us, the jobsite trailer is almost as permanent as the facilities we build.

At Pepper, we regularly address the tools and equipment we use – trading in the old and inefficient and investing in everything from electric forklifts to flat-screen monitors – to make our teams more productive. This year, inspired by the feedback we've received and my own mission to improve construction conditions, I decided to explore a new concept for an office jobsite trailer.

An authentic and functional solution

Driven by the desire to reduce emissions, rather than upgrade a few features, I wanted to know: What would it take to provide the optimum environment – where the trailer produces as much energy as it consumes? To go from producing 53,712 pounds of CO2 emissions each year (the equivalent of four residential homes) and reducing the carbon footprint to zero?

Other companies have created sustainable and Net Zero trailers, but have they used them in the field under true construction conditions? I wanted to create something that Pepper would use – that is cost effective and practical to build, transport and stage – and that would influence others in our industry to follow our lead. So, I engaged our Integrated Construction Services (ICS) group to design and price a Net Zero trailer.

We partnered with different trades and suppliers to furnish it with comfortable materials and finishes and tapped our own craftspeople to build it – with a BIM model using a HoloLens, of course.

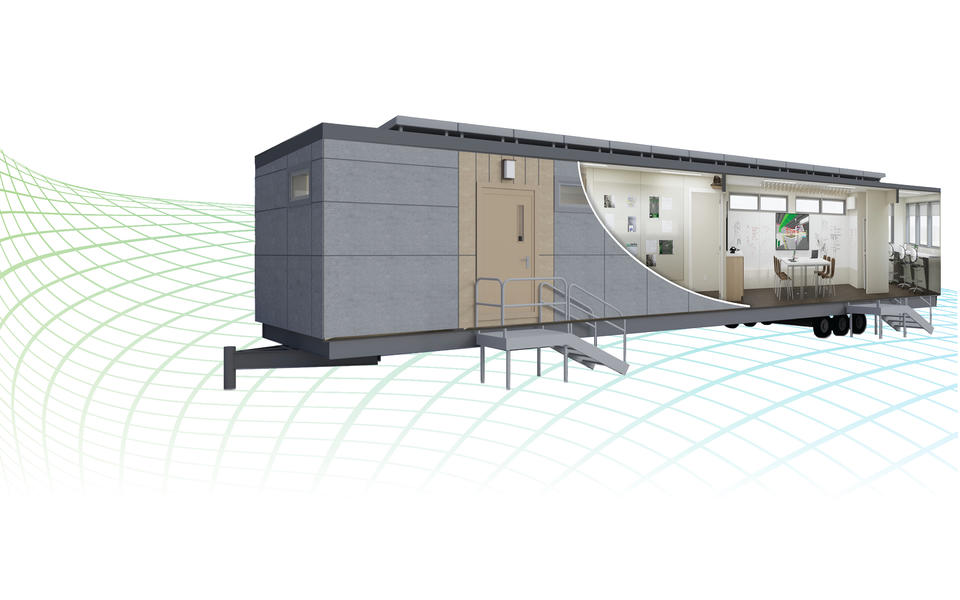

What makes up a Net Zero trailer?

- Cement fiber panels that reduce heat absorption and a thermal barrier from 6 inches of rigid insulation and 3 inches of spray foam.

- Wood framing to decrease thermal bridging, fabric panels and white board painted walls.

- 27 SunPower® E-Series Commercial Solar Panels, which generate enough kWh of energy to exceed the daily demand of the trailer, making it net positive.

- Red List-free furniture and materials, stand-up desks, writable surfaces and full-amenity kitchens with reclaimed wood.

- Acoustical panels and sheetrock that are low VOC-emitting and GREENGUARD Gold Certified.

- Low consumption lighting with integrated occupancy and daylight sensors. Lights can be reconfigured without rewiring in the future.

- Double pane, low-Argon glass windows with transparent window shades for glare control.

- Energy Star appliances and water-efficient fixtures.

- Walk-off mats and green cleaning supplies.

These are just a few of the features. Click here to read more about the trailer design and materials.

Last year, we introduced our Net Zero trailer at GreenBuild, where attendees learned about Net Zero and what went into making it.

Of course, not everything went as planned.

It’s true that sometimes we're our worst client.

- Our original design came in significantly higher than would make it practical to use on a jobsite. So back to the drawing board we went.

- We swapped out materials, even while it was already under construction. Hello re-work.

- After adjusting the design and realizing that the energy demand from technology exceeded what would be generated, we almost had to give up achieving Net Zero and limit our goal...until we finally found the right formula.

The cost to replicate.

The big question every industry partner wants to know: How much does a Net Zero trailer cost? Our design came in at 20 percent more than a conventional trailer. Yes, there is a premium for being more efficient, but equalizing the two types of trailers (making both paperless, etc.) when running the energy model and calculating operating costs, the savings that are generated pay back that difference in less than a year.

The future is now.

If we want to walk the talk, Net Zero jobsite trailers have to be our future. For Pepper, that future is here. We were proud to display a solution at GreenBuild that can truly make a difference, for our people and for our industry, for many years to come.

The Net Zero Trailer has received regional, national and international awards, including the H. Bruce Russell Global Innovators Award from CoreNet Global. After using it on multiple jobsites, Pepper is proud to partner with Craftmen Industries, Inc., the company that will be manufacturing and selling the Net Zero Trailer. To learn more, visit their website at https://www.craftsmenind.com/net-zero-trailers or go here to request information: https://www.craftsmenind.com/net-zero-trailer-request.

About the Author