Trade partnerships

When I was interviewing with Pepper Construction 18 years ago, I shared my personal philosophy for how I work with subcontractor partners. It was simple: I believed that I could not be successful as a contractor unless the subcontractor partners were successful as well. Pepper shared my position then and we emphasize it now.

Twenty years ago, working with subcontractors was not as collaborative as it is today. Over the years, I believe that there are many factors that have contributed to these improved relationships.

- A move toward more collaborative delivery methods, like CM at risk, design-build and integrated project delivery (IPD), and away from the traditional design-bid-build process.

- Increased adoption of lean construction principals, like pull planning, design-assist, daily huddles and multi-trade prefabrication.

- The use of building information modeling (BIM), which bridges communication gaps and integrates our trade partners into the upfront planning.

Inviting our trade partners into the planning process is one way we can set them up for success. The project plan becomes their plan, and they are committed to making it happen. Further, by collaborating with them during preconstruction, coordination and pre-installation meetings, often we end up with better strategies for construction.

This past year our trade partners contributed significant ideas, both before and during construction. Ideas that have kept the public and our tradesmen safer, improved the quality of the finished product, improved the schedule, and ultimately reduced the cost to our clients. Below are but a few examples:

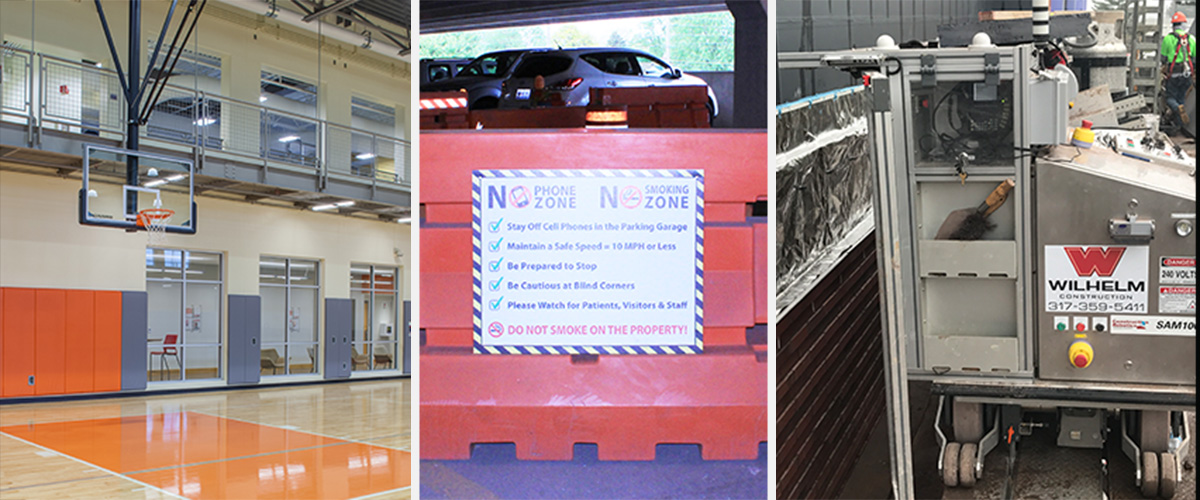

- On the Toyota T+Rex Recreational facility, the electrical trade coordinated with the precast fabricator to locate and install the electrical rough-ins within the precast wall panels during the fabrication of the panels, providing a cleaner finished product than the surface mounted conduit and box installation originally contemplated.

- At Community Hospital East, the tradespeople noticed when driving through the garage that the public was texting, speeding and generally not paying attention. In collaboration with Pepper, custom signage was created and installed as a reminder for everyone to slow down, use caution and be mindful of their surroundings. In addition, as an extra measure to reduce dirt and dust from entering the hospital, the safety leadership team suggested that boot cleaners be placed at every hospital entrance.

- On the Purdue University Flex Lab project, in an effort to expedite the completion of the brick on the exterior envelope, the masonry contractor introduced SAM (Semi-Automatic Mason) to the project, one of the latest innovations in robotics and automated technology drivers for the construction industry.

These are only a handful of examples of how innovation and collaboration with our trade partners have raised the bar on our projects. Last month, we were recognized for the second year in a row with the Indiana Subcontractors Association 2017 General Contractor of the Year award. While it is certainly an honor to be acknowledged in this way by our trade partners, without their hard work and willing collaboration, we would not have received the award.

As we celebrate our success, we want to take the time to recognize the contributions of our subcontractors as well. In the coming months, we’ll be sharing more stories of how we’re collaborating with our trade partners to provide more meaningful solutions on our projects.

About the Author