Indy 25th anniversary, Self perform, Virtual construction & technology

Most true general contractors self-perform. But the execution of their programs can differ.

For Pepper Indiana, we've always had a hands-on approach so that we can bring the highest level of quality to our clients. Since day one, we've self performed, even though we didn't have a designated self perform group at the time.

As our operations grew throughout the years, so did our goals. We knew that if we wanted to ride the trajectory of providing better, more comprehensive services for our clients, we needed to establish a separate group within our own company.

Why we self perform

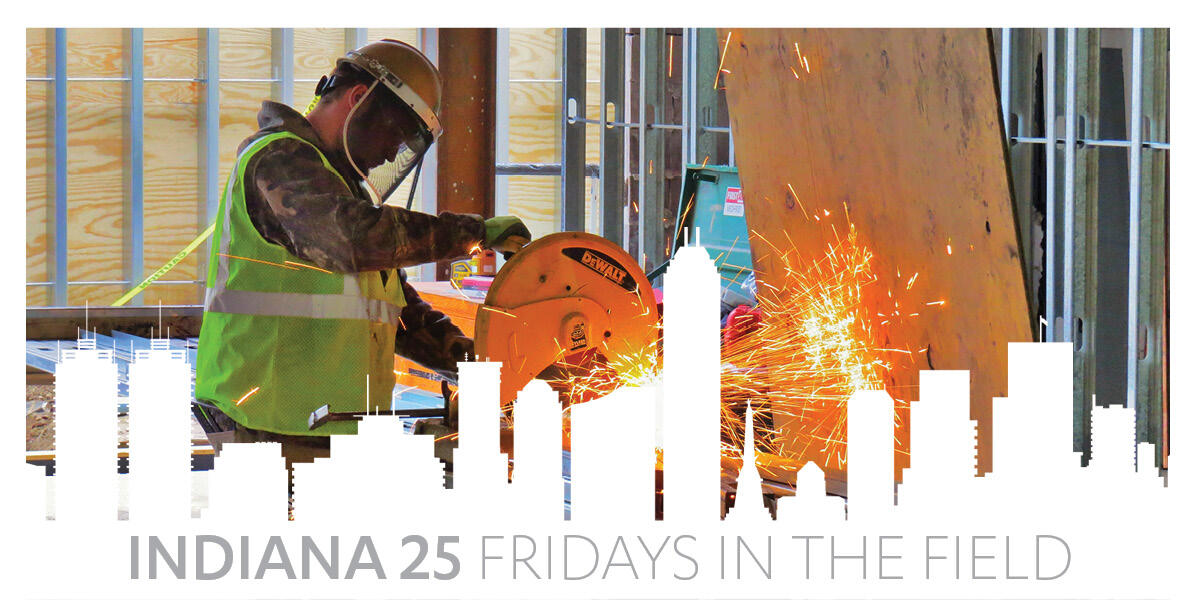

In the late 2000s, we developed our self perform group and decided to focus on concrete, drywall, carpentry and selective demolition. We immediately saw its positive effects.

Our self perform group gives us more control over the schedule and quality of our projects, which is important as we've continued to take on bigger projects. It enables us to accelerate work when needed, be more responsive and adapt to changes, gain efficiency and offer better solutions when challenges arise. The more control we have over the projects, the faster we can react for our clients.

A different model expands our reach

While most general contractors self perform concrete and carpentry, over time, we've also developed a model that includes drywall, which allows us to take on bigger projects. It also enabled us to reach a major goal of working for entities other than ourselves. We now work directly for developers and self perform work for clients on projects where we're not the general contractor.

And we're still setting new goals.

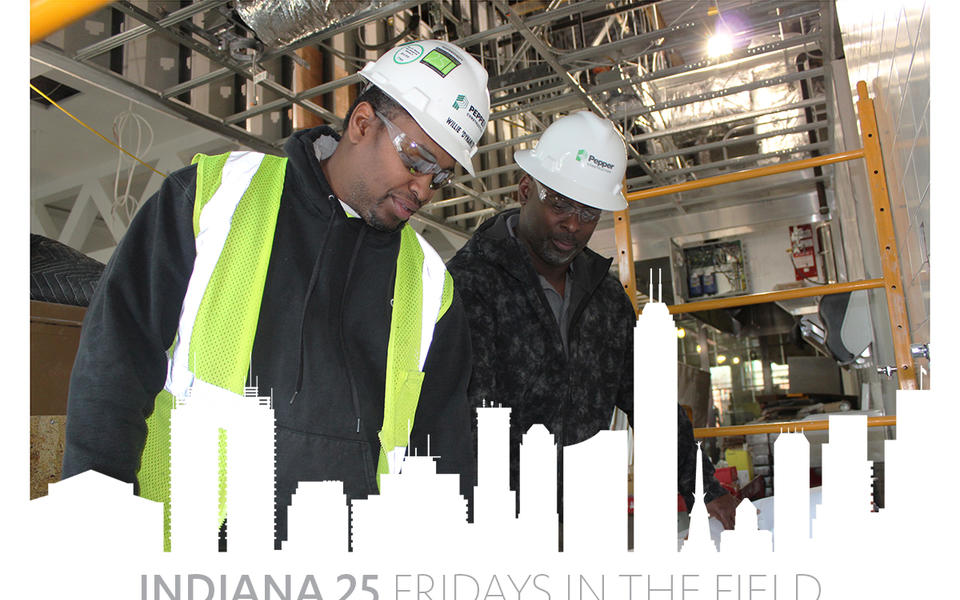

Technology advancements with self perform work

About five years ago, Pepper Indiana started exploring the use of new technology such as virtual construction and advanced equipment to aid our self perform group. Within the last year, we've ramped up our use of technology within the self-perform group, from working with our virtual construction department to adopting more sophisticated layout equipment.

One of the most successful examples has been the use of a dual laser layout system. As an alternative to a tape measure layout, we use two lasers to mate up and lay out corners of walls, bulkheads, MEP, ceiling wires and more, at an average of 10 seconds per point. The virtual construction department and self perform group then go over the CAD files loaded into the tablet that controls the two lasers. The process takes about half the time as a traditional tape measure layout and provides accurate measurements every time.

Our self perform group has continually evolved over the last 25 years, and implementing technology as we self perform is just the latest chapter of adaptation. Every new idea, equipment and piece of technology leads us toward a more efficient, higher quality process on our job sites.

What's good for our projects is good for our clients.

About the Author