High performance & sustainability, Environmental

How high performing indoor environments can make you smarter, healthier and happier - and save you money

Indoor comfort has been directly linked to productivity rates. When we're happier, we're healthier, we show up to work and use fewer sick days. A recently-published study by Environmental Health Perspectives about green buildings and cognitive function, found a strong direct connection between cognitive function and the indoor environment, leading to optimal performance and improved productivity.

People working in an environment with low VOC emitting materials and increased ventilation had significantly higher cognitive functions than those in a traditional, conventional space. In fact, in some cases the people in these green environments outperformed those in conventional environments by 200 percent. Past studies published by the United States Environmental Protection Agency and Environmental Health Perspectives, support this finding, confirming that the brain functions at a higher level when there are fewer pollutants in the air.

High performance and sustainability are about healthy environments and the health of those who occupy them. Considering that 90 percent of our time is spent indoors, we should care about the environments we create. For a long time the education and healthcare sectors have sought out better facilities that are more conducive to learning and healing – and as they learn more, they're also giving attention to the environments needed for educators and care givers to perform at their best. In the business world, companies like Google are taking the lead. Locally, brokers like CBRE and PwC are also considering productivity factors.

Why is it important to consider low or no VOC emitting materials?

Over time materials break down and emit pollutants, which we breathe in. Many are bioaccumulative, meaning these toxins build up in our bodies over time, so our immune systems are fighting off toxins every day and not just when we're sick, making it harder to get over an illness and in some cases causing us to get sick.

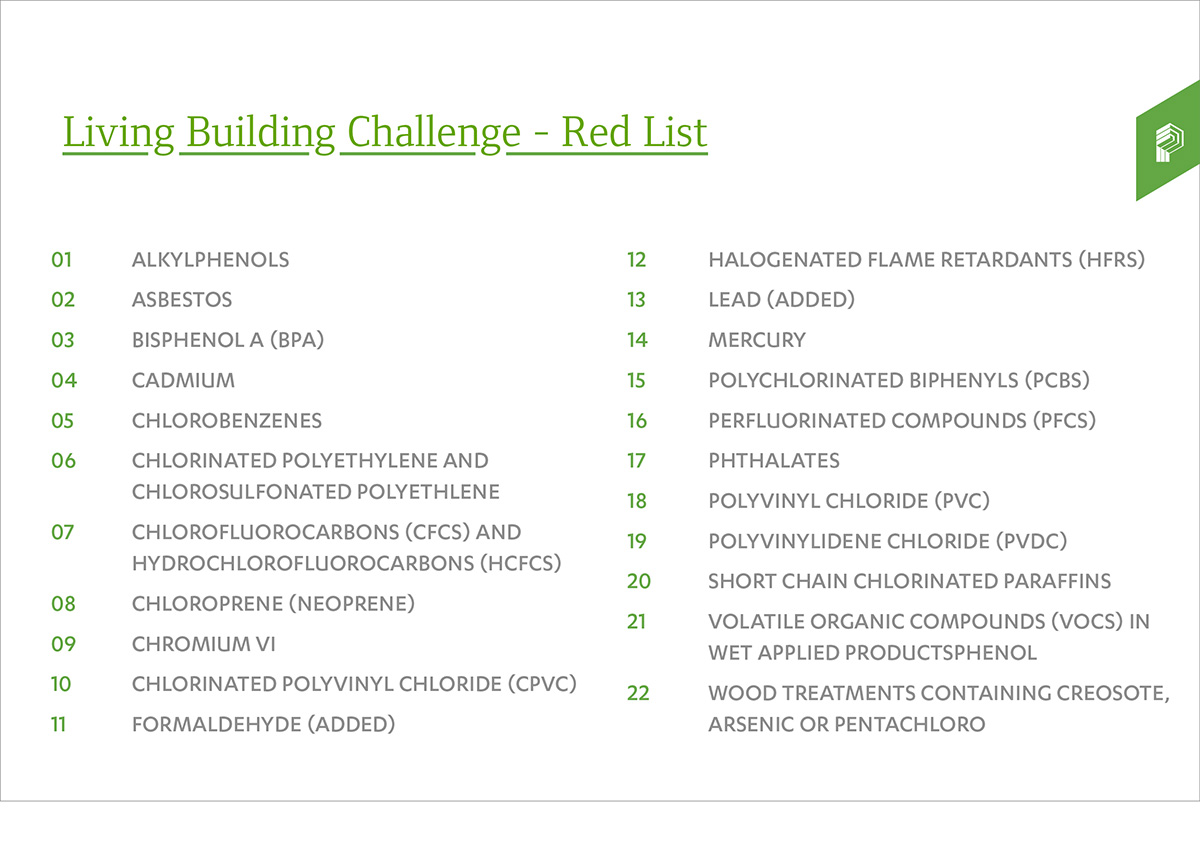

Eliminating dangerous materials like those found on the Living Building Challenge (LBC) Red List, such as asbestos and formaldehyde, is an important first step. More and more companies are considering alternative, healthier materials for paint and flooring selections and even HVAC systems.

The Red List represents 22 ingredients deemed worst-in-class that are found in our everyday building products. These 22 ingredients represent 815 chemicals. It’s similar to understanding a Twinkie is made up of cake and cream, but when you dig deeper you find out that the Twinkie's cake and cream are made up of 30 different ingredients.

What about cost?

More and more we're seeing requests for facilities to be built or renovated to LEED standards, whether or not they pursue certification. Owners recognize the benefits of sustainability for their building and operations and want to invest in high performing systems and structures.

When it comes to the materials that are selected, common misconceptions remain about the cost and durability of green products. While several green materials have higher first costs, increased demand is making the difference less significant and the products more affordable. The truth is that often healthier products can actually cost less and be just as durable. Still, the move to greener materials has been slower to take off than investments in building systems.

What should owners incorporate into their buildings to impact performance?

First, they should look at all materials and systems going into the space and consider the impact on employees. People need both calming and energizing stimulants to make our brains function. For example, in an office setting, the positive ions from our computer screens makes us tired, creating the need to get up and walk around. Fluorescent lighting has the same effect so the trend is moving toward energy-saving and color-changing LED lighting to boost our energy levels.

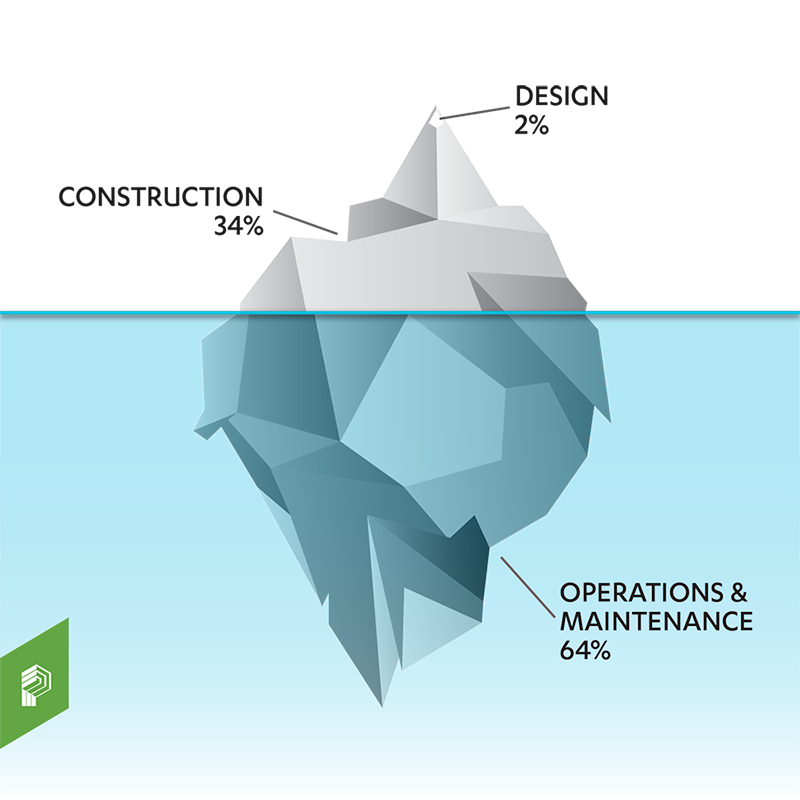

Second, owners should consider the total cost of ownership. Like an iceberg, what you see on the surface (first costs) is only a fraction of what is underneath (operating costs). Typically, design accounts for two percent of the costs, construction is 34 percent and maintaining the building accounts for the remaining 64 percent. Yet, this hidden 64 percent isn’t always considered the largest piece of the pie when going through the building design and construction process.

By looking at a lifecycle cost assessment and high performance criteria including future building operations, you will develop a more accurate cost strategy. This is best done during the design and preconstruction phase, when the information can still impact the design and materials. During preconstruction, we read through the design narrative, specification book and drawings to make sure the project's budget aligns with the design intent, looking specifically for items that affect building performance and sustainability.

For the green materials that have higher first costs, often the maintenance is low enough to provide payback in a short amount of time and bring the cost down over the life of the facility. For example, today, one of the most common enhancement opportunities owners are considering is LED lighting technology, which lasts longer and burns cooler. This provides value to operations and maintenance in three ways.

- Fewer light bulb replacements so material costs decrease.

- Reduced need for the HVAC system to make up for the extra heat emitted by lighting.

- Better eye health for improved occupant comfort.

Another area that has significant influence on the performance of the end user is the HVAC system. Sick building syndrome brought attention to the impact of poor ventilation and filters. The latest push is to use direct supply/direct exhaust systems that take outside air and push it out again so every supply brings fresh air.

Why do materials and systems matter during construction?

During installation it is important that we control the presence of moisture, particularly around softer materials like drywall, ceiling tiles and insulation, because of the potential for mold growth. Likewise, ductwork can be a breeding ground for mold so we use proper barriers and HEPA filters, keep materials wrapped and stored in a dry area – or delivered in time for installation - and we put in place thorough safety, quality and housekeeping plans.

Our guys are on the front lines of creating these environments. Installing unhealthy materials every day builds toxins in their bodies over time so the more we can handle healthy materials, the better. While we don't dictate the materials we install, we can control how it gets installed. We've started a program called Nothing Hits the Floor, which challenges our teams to use a robust indoor air quality management plan and to deliver and install all materials within 48 hours. It's simple; the cleaner the jobsite, the safer it is and the leaner it is. Limiting activities to specific areas makes it easier to wear the right protection, and it's safer and cleaner to keep materials elevated off of the floor.

In addition to a safer and cleaner worksite, we have found these programs result in higher quality installations through a controlled setting, promote a lean culture and create a healthier environment for us by limiting our teams' exposure to materials – all of which improve our performance.The Environmental Health Perspectives study brings good news. The more we learn about what makes us work at our highest potential, the more we can ensure these influential factors are in place to improve our performance. And the more we learn about our environments and our relationship to them, the better off we will be for years to come.

This post was originally published in January 2016 under the title: The impact of indoor environments on our lives. It has been edited to include an updated discussion about cost.

About the Author